Traditional SCMs include byproducts like fly ash and slag, but as these resources become less available, this project explores new sources, particularly those derived from construction and demolition waste. When concrete is demolished, it produces fine powder known as RCFs. With specific treatment, these fines can potentially enhance concrete performance when used as SCMs. However, RCFs can vary in quality depending on their source and may contain impurities that affect their effectiveness.

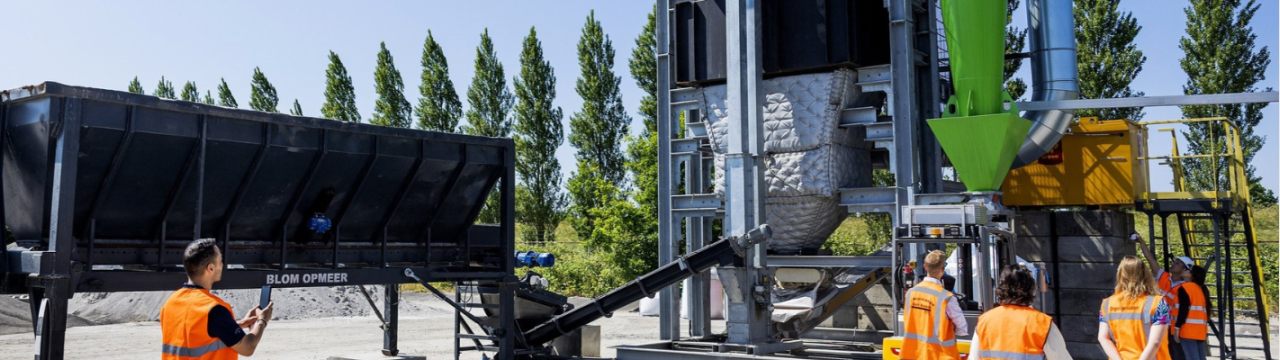

This project aims to understand how the C2CA recycling process can effectively upcycle concrete with various impurities, such as bricks and ceramics. By investigating these materials, we seek to determine how to produce high-quality SCMs. Firstly, methods will be developed to improve the properties of recycled concrete, ensuring strong and durable end products regardless of their origin. Secondly, this project will explore blends of RCFs with other mineral residues, such as dredged sediments or excavation waste, to create new, high-performance SCMs. Thirdly, lab-scale tests will be conducted to evaluate the performance and durability of the new SCMs, ensuring their reliability for construction applications.