Quantitative material characterization

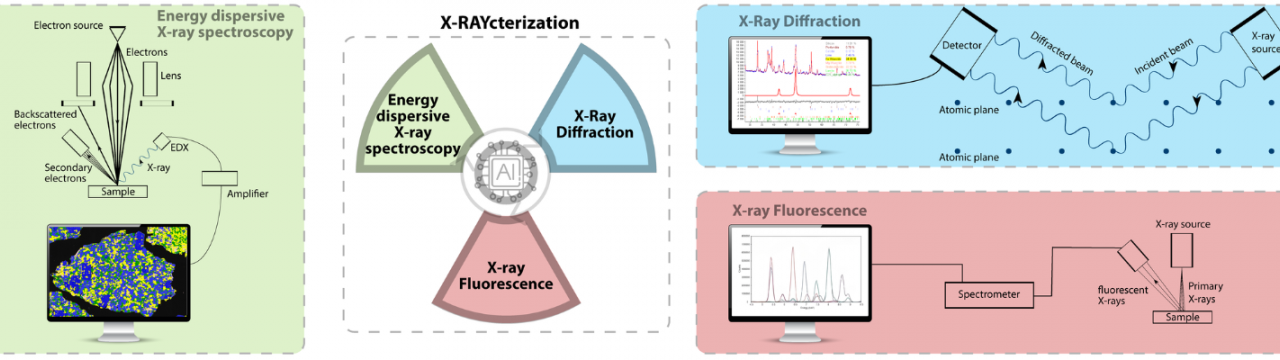

Nowadays, complex multicomponent materials can be analysed with high accuracy using X-ray Fluorescence (XRF) to determine bulk chemical composition and Scanning Electron Microscopy – Energy Dispersive X-ray spectroscopy (SEM-EDX) to assess microstructure and elemental distribution. However, this only reveals which elements are present, not the crystalline compounds they form. X-ray diffraction (XRD) analysis is the only method capable of providing this information. However, XRD doesn’t capture the elemental composition but only the symmetry of arrangement, it doesn’t see amorphous phases, minor phases, and the microstructural arrangement of phases. In conclusion, no single technology can quantitatively characterize these materials.

Computational framework for integrated material characterization

This project focusses on the industrial research of an computational framework for integrated multiphase inorganic material characterization. It will be the world’s first platform to fully unify three complementary modalities SEM-EDX-SI, Rietveld-XRD, and XRF, into a single, consistent, automated and intelligent material characterization system. The approach correlates the microanalysis (SEM-EDX-SI) with the phase analysis (XRD) in Quantitative Phase Analysis, and performs rigorous consistency checks on the results with independently obtained bulk chemistry (XRF). To facilitate this cross-correlation, it leverages artificial intelligence to automate the decision-making process that traditionally required highly educated experts.

Consortium and impact

The project will be executed by the TU Eindhoven and CarbonsAI. TU Eindhoven performs research on the crystallography, while CarbonsAI will execute cutting-edge R&D of Artificial Intelligence models and algorithms for cross-correlation of the modalities and automated expert decision-making processes. This creates a breakthrough computational framework which revolutionizes material characterization, thereby creating the technological promise to understand the nature of secondary materials, and improve circularity of industrial processes. The project thereby contributes to innovation domains ‘Imaging Technologies’ and ‘Smart Industry’ of the National Technology Strategy (NTS).