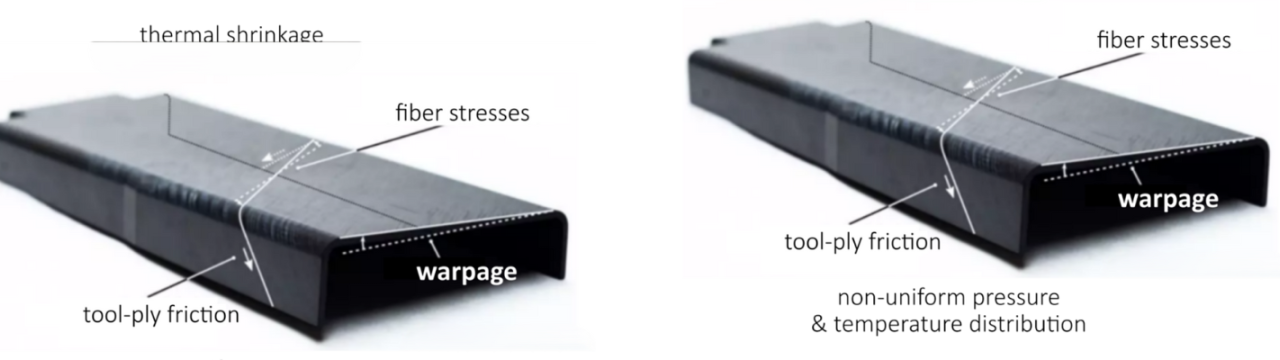

Thermoplastic composite (TPC) are ideal for producing lightweight, complex, assembled structures at high production rates. TPC parts can be efficiently assembled into larger structures using advanced welding techniques, but these methods impose stringent requirements on the dimensional accuracy of the parts. Current practice relies on costly trial-and-error tool reworkings to compensate for process-induced shape distortions.

The project FITTING aims to enable first-time-right manufacturing of high-precision 3D press-formed TPC panels by developing advanced simulation tools and experimental characterisation methods. The project focuses on shape distortions caused by process-induced stresses, incorporating second-order effects such as an inhomogeneous temperature distribution, fibre tensioning, stress relaxation, which are often overlooked and thus hampering accurate predictions and effective measures to prevent tool rework or remanufacturing. In collaboration with TPRC and AniForm, FITTING emphasizes industrial applicability, advancing sustainable aerospace manufacturing.