Stable interfaces on pure silicon electrodes

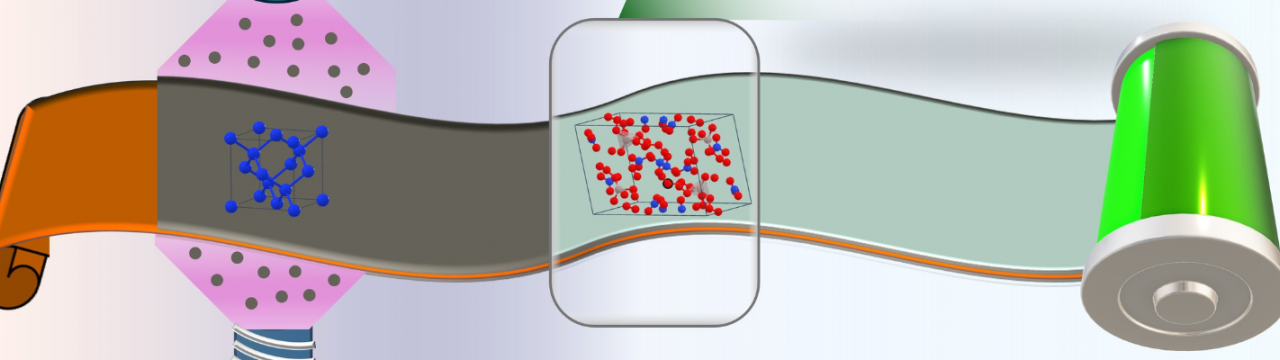

The FRISBI project aims to establish an industrially compatible, scalable vacuum-based processing route for double-sided lithium-ion battery (LIB) electrodes. Silicon is a promising electrode material for high-energy LIBs, but it typically exhibits poor cycle life as an anode due to interfacial instability. After silicon is deposited on both sides of the current collector, it will be coated using a roll-to-roll (R2R) spatial Atomic Layer Deposition (sALD) process. The deposition of an artificial solid SEI will improve cycle life and increase battery manufacturing energy efficiency. A dedicated system capable of processing double-sided electrodes will be developed for this second process.

Combining PECVD and sALD

FRISBI combines plasma enhanced chemical vapor deposition (PECVD) for the deposition of silicon and spatial ALD for the deposition of an artificial SEI. The PECVD process will be optimized for uniform double-sided coating, and for the sALD process a dedicated gas bearing transport system will be implemented and optimized. The result is a reliable and robust roll-to-roll sALD system, which covers the anode material in a conformal manner and can coat double-sided electrodes. Suitable solid electrolyte interface (SEI) materials (e.g. aluminium oxynitride) will be developed that are resistant to contact and flexible enough to accommodate the electrode volume changes during charge and discharge.

Kalpana Systems and TU Delft

In the FRISBI project, the expertise in the field of film transport in R2R ALD systems of Kalpana Systems, is combined with the knowledge of the TU Delft. Where Kalpana Systems currently offers the only commercially available high-throughput R2R ALD system in the world, TU Delft has a large expertise in the field of scalable development and electrochemical analysis of (silicon) anodes, their degradation by charge/discharge processes and their vulnerability to microscopic damage. Kalpana Systems’ and the TU Delft’s joined efforts in this project could lead to commercially viable solvent-free fabrication of LIB anodes with high energy density and extended cycle life.