Mechatronics from the Netherlands is a silent force behind many technological achievements, from ASML's chip machines to robotic arms that assist surgeons in delicate operations. Good news: according to Ton Peijnenburg, program council member at Holland High Tech for the innovation domain Mechatronics & Optomechatronics, there are also great opportunities for the Netherlands in the future. “Dutch mechatronics plays a crucial role in the Einstein telescope, among other things.”

Photo credits: ©Marco Kraan/Nikhef

This article is part of a series we're producing in collaboration with IO+. It introduces you to all the innovation domains of Holland High Tech. In this installment: the Mechatronics & Optomechatronics innovation domain.

Mechatronics, the art of merging mechanics, electronics, and software, is all around us. Take ASML's ultra-precise machines, which manufacture chips at the nanometer level. In healthcare, mechatronics is everywhere: from robots that deliver food to hospital rooms to surgical robots that can perform procedures more safely and precisely. A recent report shows that the European market for agricultural robots and mechatronics will also double between 2025 and 2030. This is not surprising, as autonomous robots and advanced laser systems are gaining ground in the sector.

In short, mechatronics is increasingly shaping our daily lives and our future and that offers opportunities for the Netherlands. “Our country is fully committed to this: mechatronics and optomechatronics, precision mechatronics with light and optical systems, have been explicitly designated as key enabling technologies in the National Technology Strategy,” explains Peijnenburg.

A rich history

First, let's go back in time. Mechatronics has deep roots in the Netherlands. Peijnenburg knows this better than anyone. He started at Philips in 1992, in what was then the Philips Center for Manufacturing Technology, where mechanics, electronics, and software came together in a single development environment.

At the time, Philips was working on the development of the CD and later the DVD, among other things. “Precisely aligning a laser to read data from a disc seems simple, but it requires perfect interplay between mechanics, electronics, and control technology,” says Peijnenburg. Those same principles now form the basis for ASML wafer steppers, among other things. “Those machines are much larger and more complex, but the underlying mechatronic philosophy is the same.”

At that time, it was already clear that the Netherlands was doing well in the field of mechatronics, for several reasons. First, the technology itself: accurate positioning, precision mechanics, and control technology. Second, the way of working: multidisciplinary, system-oriented, creative, and non-hierarchical. “The Dutch don't wait for instructions, we take matters into our own hands. In many other countries, systems are hierarchical, which means that decision-making takes longer. That speed gives our mechatronics a big advantage.” Thirdly, the ecosystem: the Netherlands has a solid foundation, partly thanks to a long history with companies such as Philips.

From major players to innovative startups

Fast forward to today: the Netherlands is teeming with mechatronics companies, from major players to innovative startups. Trabotyx combats weeds in agriculture completely autonomously with lasers, in a sustainable manner. ASML plays a global role with ultra-precise machines for chip production. In the medical field, companies such as Preceyes are developing mechatronic robots for eye surgery, enabling surgeons to perform extremely precise procedures.

Optomechatronics has also grown significantly in the Netherlands in recent years. This field combines precision electronics with optical components for applications such as measuring instruments. A good example of a Dutch company active in this field is Demcon.

The sector is currently flourishing, partly thanks to Holland High Tech, the top sector for High Tech Systems and Materials. Companies, knowledge institutions, and governments work closely together on multidisciplinary innovations. One of the innovation domains focuses on mechatronics and optomechatronics. Holland High Tech supports the ecosystem through multiple strategic programs and public-private partnerships. For example, the Semiconductor Manufacturing Equipment program links knowledge institutions to the semiconductor industry. With the participation of companies such as ASM, ASML and ZEISS and universities such as TU/e, UTwente en TUD, precision instruments are being developed that secure the chip roadmap. Mechatronics is indispensable in this. Innovation in (opto)mechatronics also plays a major role in the strategic programs Medical Technology and Advanced Instrumentation.

NWO also regularly organizes calls in which government, companies, and knowledge institutions collaborate on mechatronics projects. For example, in collaboration wirh the Knowledge and Innovation Agenda Key Enabling Technologies (KIA ST) the KIC-call System design in mechatronics and optomechatronics aims to optimize (opto)mechatronic systems that enable the development and construction of high-tech instruments and machines. Researchers are invited to conduct interdisciplinary research in broad consortia with partners from different sectors.

Opportunities for the future: satellites and the Einstein Telescope

The Netherlands' expertise and innovative strength will continue to be crucial in the coming years, both within and beyond its borders. First, geopolitical tensions make secure communication methods more urgent than ever. A good example is a collaboration between TNO, VDL, and Demcon on satellite communication. “These projects involve working on modules in which mechatronics and optomechatronics work closely together: lasers and other precision components function seamlessly together,” says Peijnenburg.

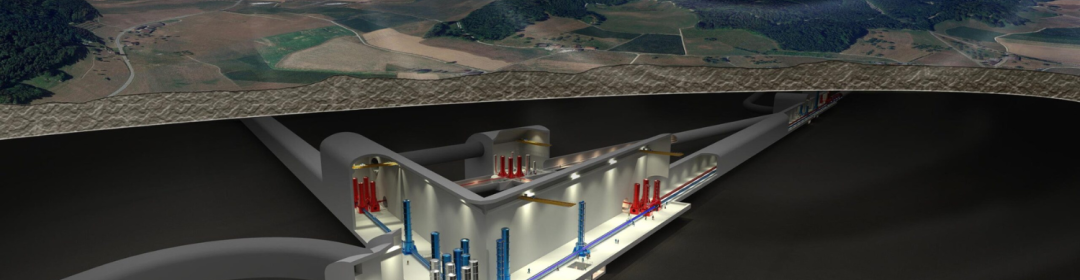

Dutch mechatronics also plays a crucial role in another large-scale project: the development of the Einstein Telescope. The mechatronics expert continues: “This is an advanced instrument that detects gravitational waves and thus provides fundamental insights into the structure of the universe. VDL is also involved in this project. Each arm consists of enormous vacuum tubes. Maintaining a stable, deep vacuum over such distances requires advanced mechatronics – pump systems must be strategically placed and the entire installation must be aligned with extreme precision. Moreover, it is not just about the tubes themselves, but also, for example, about controlling the mirrors, which requires mechatronics.”

Peijnenburg expects that the techniques used in this project will later be widely applicable in society. “We are tackling fundamental technical challenges that could lead to spin-offs for other high-tech applications.”

But we must remain realistic. The Netherlands may be developing the systems of the future, but there are still plenty of challenges that need to be addressed within the country's borders. “One of these is increasing energy consumption,” explains Peijnenburg. He again cites the semiconductor industry as an example. "Chips are becoming smaller and more precise, which means that the machines are becoming larger and more complex. Whereas the first ASML machines were the size of a refrigerator, modern machines are now as big as a building. Energy consumption has therefore increased significantly. This calls for new materials, more efficient processes, and, consequently, smart mechatronics," he concludes. In other words, there will be plenty of work for the mechatronics sector in the coming years.

Other articles in this series: