In the current geopolitical climate, Europe must strive for strategic autonomy, including for raw materials, and therefore focus on circularity. The Sustainable Smart Industry Lecturers' Platform aims to contribute to this through research into the sustainability of the manufacturing industry. Projects address related themes such as sustainability compliance, access to raw materials, labor shortages, and remanufacturing. Key technologies that play a role in this include digital information technologies (AI, digital twinning, data engineering, augmented reality), engineering, and manufacturing technologies (robotics, digital work instructions).

This article is an initiative of the Universities of Applied Sciences Key Technologies Thematic Table. The goal of this national partnership is to better demonstrate the impact of practice-oriented research by universities of applied sciences in the field of key technologies.

Challenge

New geopolitical circumstances and rapid developments in this area have far-reaching consequences for European industry. Global competition, protectionism, market disruptions, and trade tensions are all increasing. The international trading system, as laid down in agreements within the World Trade Organization (WTO), is increasingly under pressure.

The rise of China as an economic power exacerbates these challenges and places significant pressure on European industry. Furthermore, the availability of scarce metals is crucial for European industry, especially given the geopolitical tensions and its dependence on imports from countries like China. China's control over the supply chains of critical raw materials (such as palladium and cobalt) gives it a strategic advantage and makes European industry vulnerable. This underscores the need for Europe to focus on strategic autonomy through supplier diversification, investment in its own mining industry, and a circular strategy that promotes the recycling and reuse of these raw materials.

To further reduce dependency, Europe is strongly committed to circularity. This means shifting the focus to raw material reuse, more efficient material use, and product and supply chain redesign. By encouraging the reuse and recycling of materials, the demand for primary metals can decrease, benefiting both the sustainability and security of supply for the industry.

A key tool in this circular transition is the European Digital Product Passport (DPP). This passport provides insight into the composition, origin, and recyclability of products, enabling not only the establishment of sustainable production chains within Europe but also the elimination of products from outside the EU with polluting and harmful chains. This policy therefore serves a dual purpose: on the one hand, the internal sustainability of European industry, and on the other, strengthening strategic autonomy by reducing reliance on unsustainable import flows.

The Sustainable Smart Industry Lecturers' Platform focuses on making the manufacturing industry more sustainable. This presents companies with various dilemmas, which the platform aims to address through applied research. For example, how do we handle sustainability-related compliance and ensure access to raw materials while also facing a shortage of human resources? How will remanufacturing change our existing manufacturing processes? How do we design digital and physical systems that contribute to this?

Results

Several proof-of-concepts have been realized in the field of remanufacturing and disassembly:

- Instruction-based disassembly with hololens

In this project, a group of ICT & Technology students from Fontys University of Applied Sciences in Eindhoven, supervised by a lecturer-researcher, worked on a proof-of-concept to support identification and manipulation activities in a disassembly process. The idea was to use vision and AI to identify the product, a bicycle battery, after which the system (running on a HoloLens) would instruct the operator to disassemble the product/its components. Feasibility checks were also incorporated to determine the quality of product components.

- DisCoBot

In this project, successive groups of students and interns from The Hague University of Applied Sciences Mechatronics have been working for the past two years to develop a cobot that can automatically disassemble multiple products from the same product family (electric motors). In this setup, the product is given a digital topology description (in a DPP-like manner). The cobot setup enriches this information using vision to create instructions for this specific project. Key interim results include the disassembly end-of-arm tools and the tool change station, developed by the students with input from the researchers.

End-of-arm tools that are developen within the DisCoBot-project.

|

Students were actively involved in the DisCoBot project.

- Digital shadow for battery management system

In this project, a group of ICT Technology students from Fontys University of Applied Sciences in Tilburg, supervised by a lecturer-researcher, worked on a "digital shadow" for a battery management system. A digital shadow was created to read static and dynamic (battery) data. The goal is to monitor batteries throughout their lifespan to determine the value of products. The data is read via an Asset Administration Shell using Basyx software.

- TECHPASS

How can digital technologies help entrepreneurs and engineers from globally operating SMEs in the high-tech manufacturing industry implement DPPs and thus achieve practical, feasible, and sustainable circular solutions? Research into this question is being conducted by the Amsterdam University of Applied Sciences in collaboration with SME partners EKB, EMT, and HGG, supported by industry organizations such as Koninklijke Metaalunie and FME. The research begins with an exploration of the current state of affairs and knowledge gaps surrounding DPP implementation among SMEs, followed by a technology exploration of digitalization opportunities. Parallel to this, circular business opportunities and design strategies are being explored through workshops and interviews with consortium partners. The insights from these activities are then integrated into concrete recommendations on DPP implementation for the SMEs involved.

SME Partner:

The Digital Product Passport is the way to become more sustainable, but it requires collaboration.

The Hague University of Applied Sciences is conducting two pilot projects (yet to be integrated) for product recognition and classification. These projects use various technologies (vision, markers, AI) to automatically recognize and classify a product, both as an isolated product and within a stack or container.

The project results above represent steps in putting the pieces of the puzzle together regarding remanufacturing. They demonstrate opportunities that businesses, citizens, and government can use to take further steps and, in doing so, involve higher professional education.

Disassembly

The Disassembly Learning Circle is a collaboration between Philips, lecturers from the Mechanical Engineering, ICT, and Industrial Automation & Robotics bachelor's programs at NHL Stenden University of Applied Sciences, and the Smart Sustainable Manufacturing research group at NHL Stenden. This learning circle has taken a significant first step towards developing an integrated disassembly architecture for reuse and remanufacturing. The result is a shared conceptual framework for disassemblability and the design of an architecture that encompasses both the physical process flow (tooling, cell design, and robotics) and the data process flow (product information, LCA data (for lifecycle analysis), and algorithms for disassembly planning).

Students and lecturers collaborate across disciplines on specific components of this architecture. Examples include the design of a smart and flexible disassembly cell, the development of algorithms for optimal disassembly sequences, and the linking of economic and ecological cost functions to decision support. The results of this learning circle form a key building block for the circular strategy of Smart Sustainable Manufacturing. It shows how education, research and business work together on solutions that contribute to sustainable production processes and value creation in the manufacturing industry.

|

The smart and flexible disassembly cell developed by NHL Stenden University of Applied Sciences with the commitment of students.

Follow-up

The projects mentioned above are "work in progress." Following the results of the Disassembly learning circle, a LLO catalyst application has been submitted, with NHL Stenden acting as lead partner. The goal is to structurally further develop learning circles focused on lifelong learning (LLO) for the smart and circular manufacturing industry. This project, SWING Transit, has been approved and will launch on 1 September 2025.

Within SWING Transit, learning circles are being established around crucial themes for the transition to a sustainable industry, including Digital Product Passport, disassembly, circular design strategies, and circular production. In these learning circles, education, research, and business collaborate to develop new LLO solutions that directly address current innovation challenges in practice. The project currently has 35 participating companies. It provides a significant boost to strengthening the northern skills ecosystem and accelerating the transition to a smart and circular manufacturing industry.

Lecturer:

The sustainable factory of the future revolves around human-machine collaboration – with technology that thinks, learns, and predicts.

Partners

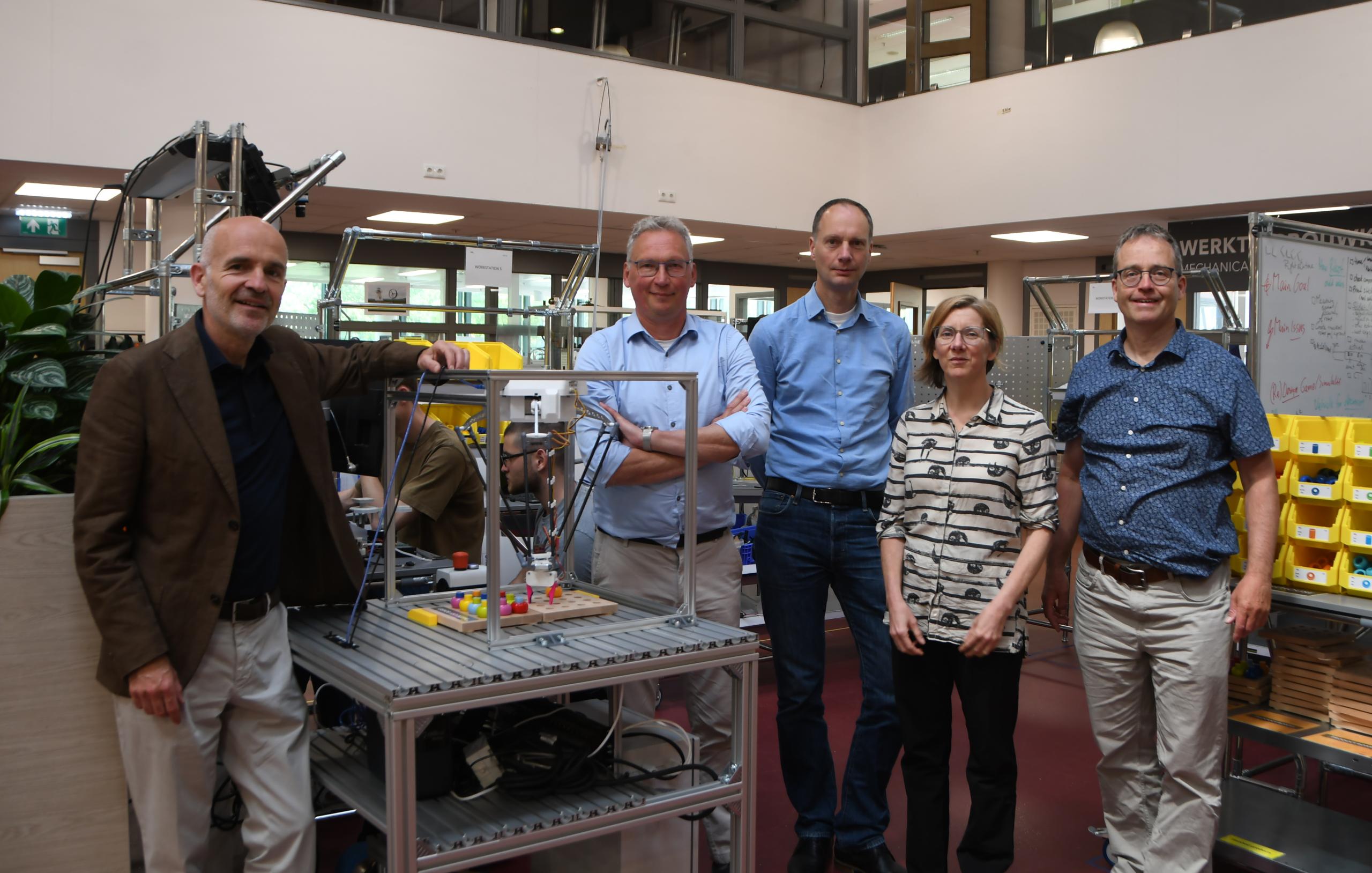

Members of the Lecturer platform Sustainable Smart Industry are:

- Amarante Böttger, lector New Materials and Applications, Avans University of Applied Science

- Jenny Coenen, lector Smart Sustainable Manufacturing, The Hague University of Applied Sciences

- Wilbert van den Eijnde, lector Smart Sustainable Manufacturing, NHL Stenden University of Applied Sciences

- Jurjen Helmus, lector Industriële Digital Twins, Amsterdam University of Applied Sciences

- Teade Punter (voorzitter), lector High Tech Embedded Software, Fontys ICT

- Aart Schoonderbeek, associate lector Industriële Automatisering & Robotica, Windesheim

- Vincent Wiegel, lector Lean, HAN

MKB-partners zijn:

- Grimbergen Automation Solutions

- Remade in Holland

- Biosphere Solar

- Botau Engineering

- S-NEW

- Werkze

- AM Flow

- Moonly

- HTC

- CS-Staal

Tot de overige partners behoren TNO, VDL en Platform Circulaire Maakindustrie.

|

Leden van het Lectorenplatform Sustainable Smart Industry voor het thema Disassembly, van links naar rechts: Vincent Wiegel, Wilbert van den Eijnde, Aart Schoonderbeek, Jenny Coenen en Teade Punter.