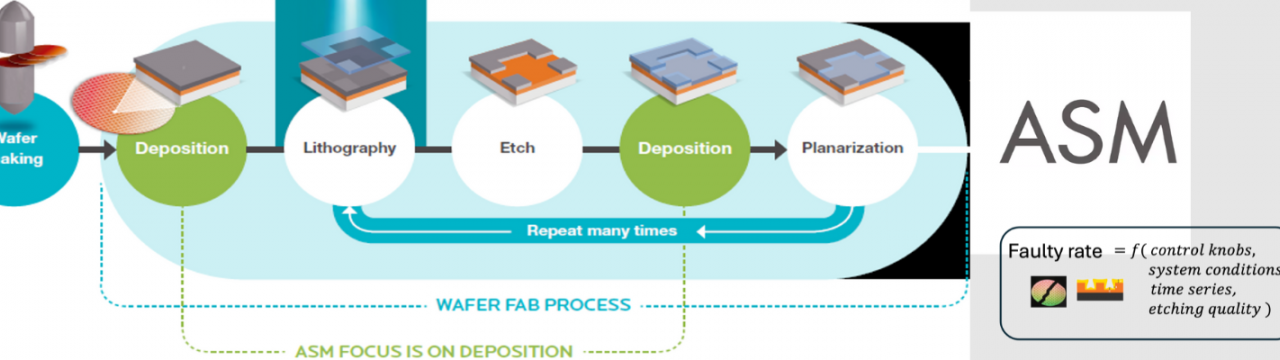

We aim to design accurate and effective time series forecasting/synthesis models that capture the performance of deposition and the wafer under a large design space of system and processing configurations. We then guide the process optimization to lower the wafer faulty rate.

To achieve such an end, we will address the following research questions: (i) how to model a large number of time series that exhibit complex spatial-temporal dependency on exogenous systems and control variables, (ii) how to update the time series models based on the real-time streams and estimated data drift, (iii) how to federate (i.e., distribute and aggregate) models across systems/processes based on their data distribution and conditions(e.g., one monolithic model v.s. multiple small models) and (iv) how to best leverage data across processes, systems, and clients while preserving the data confidentiality.

FedDepo will answer these questions in four work packages, and the expected outcomes will solve the acute anomaly prediction challenges for deposition and enable open collaboration across actors in semiconductor manufacturing without sharing data samples. Part I will specifically focus on building federated time series model and paradigm. Part II will be on the integration with data collection and contentious learning to address data drifts. We will focus on the Part I at this proposal and Part II in the subsequent proposal.