Are you a student, an engineer or a researcher in the field of Aerospace, Architecture, Design, Maritime, Materials, Mechanical, a.o. ? Are you passionate about technology and want to see your ideas take shape? Then, this challenge is for you!

The Grade2XL project organizes an open Additive Manufacturing Challenge for students, researchers and engineers.

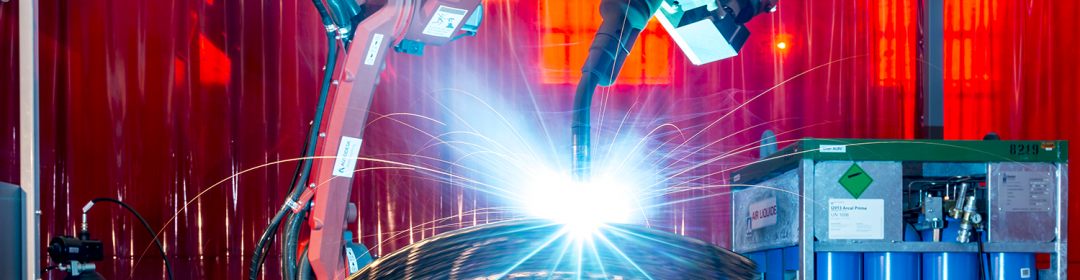

WAAM

Wire Arc Additive Manufacturing (WAAM) is the next big thing! Large engineering structures like turbines, bridges or industrial machinery are still manufactured by traditional processes such as forging, casting or by machining from solid blocks. These processes do not allow local control of material properties to achieve a specific function like anti-corrosion or hardness. To meet the functional specifications, engineers must operate within a limited range of design options, with high “buy-to-fly” ratios and long lead times. The WAAM technology overcomes those barriers to produce fully dense metallic structures with no porosity. WAAM is also unbeatable in terms of production times, making it uniquely suited for large and functionally demanding engineering structures. Next to that, using WAAM leads to a CO2 reduction up to 35% during production, reduces material use and improves the product life cycle.

The Challenge

Your mission: to design a 3D printed component that can be printed with the WAAM technology. Your idea can be based on an existing or a novel product / tooling. You can apply as individual or as a team. Submit your design before 1 November 2022.

The winner(s) will be announced at the Meeting Materials conference 2022 organized by M2i on 13 December 2022.