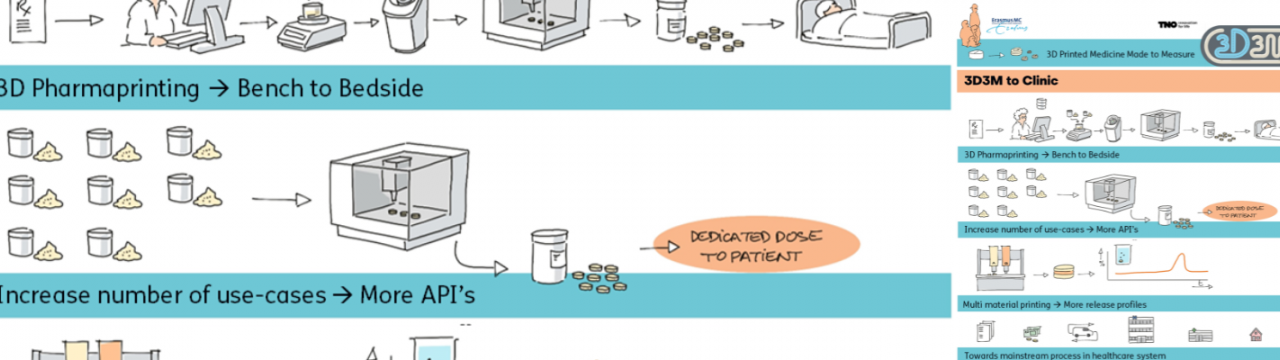

Recognizing these hurdles, 3D3M2C builds on prior research done by TNO and Erasmus MC to demonstrate the practical application of 3D printing in hospital pharmacies. By supporting clinical trials, the project validates personalized medication production and seeks to expand its application to address various other conditions requiring precise dosing.

Moreover, 3D3M2C explores the potential of multi-material 3D printing to cater to diverse patient needs, thereby enhancing versatility and efficacy in medication delivery. Additionally, the project aims to establish a robust framework for integrating 3D printing into healthcare systems, addressing technical and regulatory challenges. Through these efforts, 3D3M2C strives to lay the groundwork for widespread adoption, ensuring seamless integration into existing healthcare workflows while optimizing patient outcomes and healthcare delivery efficiency.

By combining clinical validation, technological innovation, and systemic integration, 3D3M2C emerges as a pioneering initiative poised to transform medication delivery, particularly in pediatric settings. It aims to usher in a new era of personalized pharmaceutical care, where medications are tailored to individual patient needs, ensuring precision and accessibility. 3D3M2C promises to improve healthcare management, ultimately enhancing patient well-being and safety.