The manufacturing process of thermoplastic composites (TPCs) is of crucial influence on the mechanical performance of the produced part or larger structure. This holds for virtually any process, from press forming, over-moulding and TPC welding to recycling processes including mixing and compression moulding. The distributions of the polymer matrix and the reinforcing fibres, their orientation and length define the material structure, which largely determines the local stiffness and strength.

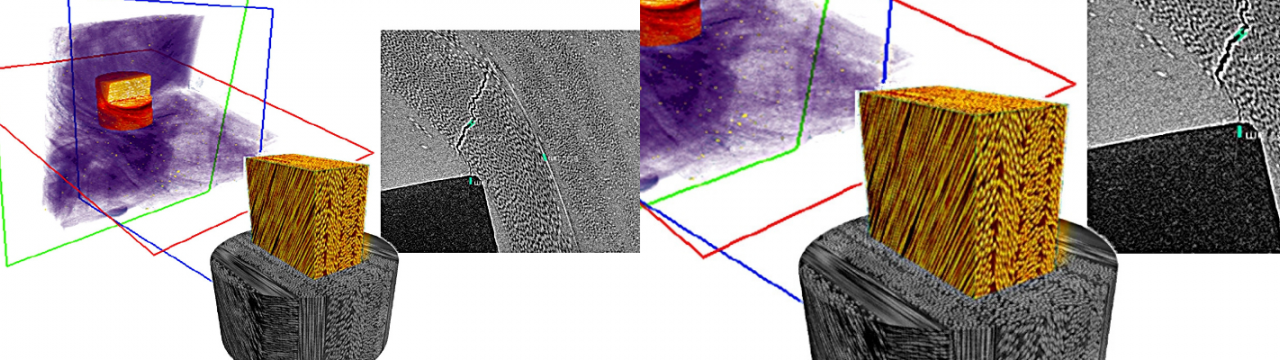

DIAGNOSE aims to measure the internal microstructure of the composites to improve reliability of virgin material and in particular enable optimised application of recycled material by means of μX-ray Computed Tomography. Novel 3D topology mapping techniques will be developed to quantify such distributions, providing an essential steppingstone towards a digital twin which can accurately describe process-structure-performance relations. Well-validated digital twins are crucial for the faster acceptance of new materials and processes in safety-driven applications in, for example, the aerospace industry.