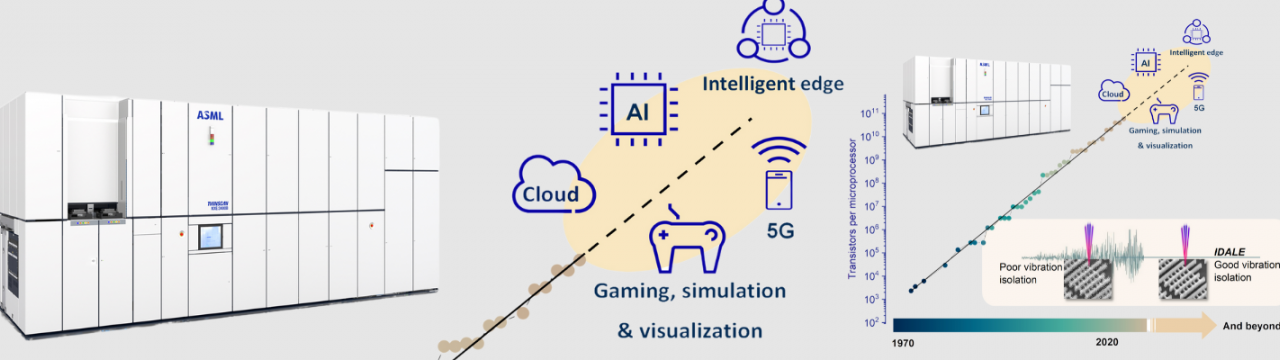

This is enabled by a development of new photolithographic techniques that are pushing the further microchip downsizing making semiconductors cheaper and electronic devices more powerful. The printing resolutions with the newest EUV technologies are as small as 8 nm, which is comparable to the atomic levels.

This requires extremely precise environmental control of the scanner. Every particle, every vibration, every wrinkle can disturb the photolithographic process. That’s why inside of the scanner is an ecosystem on its own – kept in the cleanroom and isolated from the bustle of the outside world.

The semiconductor industry largely relies on fluorine-based materials – so-called PFAS. They are omnipresent in the machine due to their unique combination of properties. All materials used in a vibrational damping control are currently PFAS-based which means that their production and disposal are connected with environmental and health risks, and soon their use will be restricted due to upcoming PFAS-legislation. This project aims at development of better performing and safer materials for vibrational damping control.