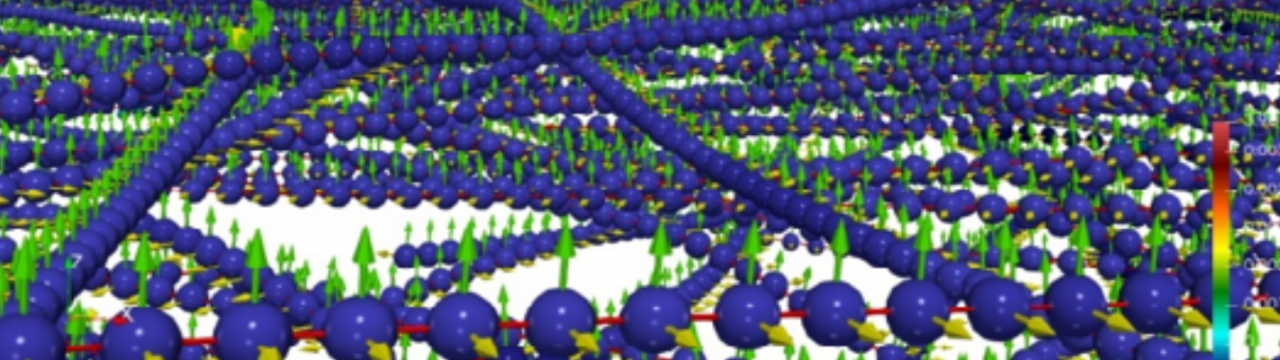

Free-standing carbon and boron-nitride nanotube (NT) membranes are the prospective candidates for extreme ultraviolet (EUV) pellicles to be used in the next generation EUV lithography machines. They can be made extremely thin, fracture-resilient, and resistant to detrimental effects of extreme environments (high temperature, free hydrogen, etc.).

Impact

However, the mechanical properties and chemical stability/inertness of NT pellicles are currently poorly understood. Our project is aimed at: 1) establishing a numerical simulation model that is capable to reliably predict the real pellicle’s mechanical properties and 2) developing strategies to extend the pellicle operational lifetime by improving the chemical inertness.