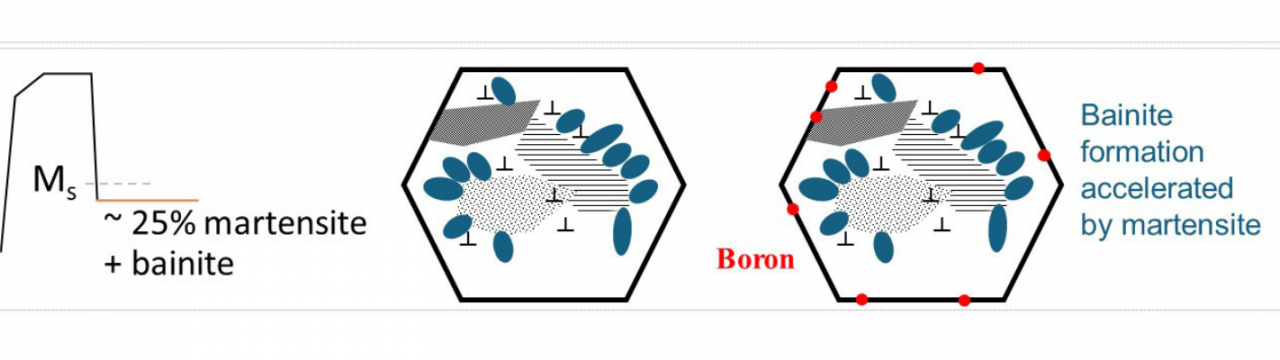

The goal of steel manufacturers is to produce strong and formable steels, which are affordable and made with simple and efficient processes. Boron is a low-cost element that improves the hardenability of steel. However, adding boron also slows down the formation of certain important structures in the steel, such as bainite, which is undesirable.

The project aims to help manufacturers make the best use of boron in developing new types of steel. Specifically, it will determine how much boron is needed for hardenability and how to adjust the production process to overcome the delays in bainite formation. This requires a deep understanding of how boron interacts with the microstructure and determine if this interaction is due to segregation to defects (grain boundaries), or due to the formation of certain compounds. Ultimately, the project will clarify how boron and its compounds impact the mechanical properties of steel. This will help optimize steel production while keeping costs low.