The Dutch high-tech (equipment) industry is a crucial pillar and innovative force for the Dutch economy. With innovative systems, Dutch companies distinguish themselves worldwide. The industry is experiencing increasing system complexity, growing global competition, and a scarcity of engineers needed to accelerate innovation. Therefore, new methodologies and techniques are required to enhance the productivity of engineers. In this programme, knowledge institutions and companies develop these methodologies, using industrial use cases to demonstrate their value and applicability.

Programme duration: 4 years | 2024 - 2027

Problem statement

The Dutch high-tech (equipment) industry is a crucial pillar of the innovative strength of the Dutch economy. With innovative systems, Dutch companies distinguish themselves worldwide. Many of these companies are ranked number 1 or 2 in their market globally. These companies have achieved this position by effectively integrating technological innovations into systems that they can manufacture, deliver, and service worldwide. Effective and efficient systems engineering methodologies, techniques, and tools that can be optimally integrated into industrial R&D and engineering processes are a necessary ingredient in the success of these Dutch companies.

The complexity of high-tech devices is immense, and so is the complexity of the processes and organisations that produce them. This complexity will continue to grow significantly in the coming years due to various causes, such as:

- the integration of systems in systems-of-systems

- the application of AI in high-tech systems and the increasing autonomous behaviour of these systems

- the enormous diversity of high-tech systems

- the critical application of high-tech systems for business processes, safety, etc.

In addition to the challenge of this explosion in complexity, the industry faces a significant human capital challenge: experienced engineering experts are scarce, and it takes a long time for new engineers to build up knowledge (domain knowledge, system knowledge, and industrial engineering knowledge in general). Therefore, the industry has a great need for methods and techniques to develop systems more efficiently and effectively.

Objective

In the Systems Engineering for High-Tech Systems programme, research is conducted into methodologies for efficient and effective (systems) engineering of high-tech equipment. The consortium envisions that the engineering of these systems will need to take place in a radically different manner in ten years’ time, considering the challenges:

- explosion of complexity

- growing international competition

- scarcity of experienced engineers

The programme operates on the vision that innovative methodologies can achieve significant productivity improvements through the combination of systems engineering and systems thinking, model-based techniques, artificial intelligence, and data science.

The programme is based on the vision that:

by 2035, the productivity of engineers in the high-tech industry will have more than doubled due to the intensive collaboration between engineers and digital engineering assistants, that can leverage models, data, and domain and engineering knowledge.

The research focuses on developing methodologies (and digital engineering assistants) that can be used by the high-tech industry to increase the efficiency and effectiveness of their engineers, thereby enhancing the innovative capacity of the Dutch industry in times of growing complexity challenges, increasing global competition, and a significant and growing shortage of engineers.

Approach

The programme will be carried out through a series of public-private partnership projects. In these projects, TNO and the academic partners will collaborate with one or more industrial partners. The industrial partners will provide the industrial environment and use cases within which the research can take place. The aim is to demonstrate, using the industry’s use cases, that the developed methodologies and digital engineering assistants are indeed usable and add value. Therefore, the research will focus not only on the technology but also on aspects that influence the actual application in the industry, such as changes in development processes, the required knowledge and skills of engineers, etc.

In the programme, five programme lines have been identified:

- Systems engineering methodologies aimed at controlling and improving distinctive system qualities (such as system productivity/performance, image quality, etc.)

- Systems engineering methodologies aimed at “life cycle excellence” (reliability, service, diagnostics, circularity, sustainability, etc.)

- Systems engineering methodologies for system families (diversity of system configurations, continuous evolution of systems, etc.)

- Systems engineering methodologies aimed at the integration of systems in systems-of-systems

- Systems architecting and systems engineering methodologies in general, aimed at the development and validation of innovative methodologies such as MBSE (model-based systems engineering), reference architectures, value-based architecting, digital engineering.

Relation with urgent transitions, KIAs and technologies

The programme conducts research into methodologies for systems engineers to enhance the innovative capacity and productivity of the Dutch high-tech industry. In this way, the programme contributes to the national earning capacity.

Urgent transitions

- Digitalisation: the programme focuses on developing methodologies for systems engineering of complex high-tech systems. Due to the increasing amount of software in these systems, the complexity of the design and the design process has risen explosively. This growth will continue unabated in the future. The programme addresses the explosion of complexity resulting from this digitalisation. This is achieved by developing data/model-based systems engineering methodologies, with the aim of deploying them as digital engineering assistants: the digital transition of systems engineering.

- Circular economy: engineering for sustainability and circularity is part of the programme. A central question to be investigated is: how can the sustainability impact of design choices be supported with model-based methodologies in the early systems engineering phases? The entire life cycle of a system must be considered. Research will focus, for example, on how this can be integrated into Model-Based Systems Engineering (MBSE) methodologies.

Key Technologies – Systems Engineering

The programme focuses on developing methodologies for systems engineering of complex high-tech equipment. It addresses a wide range of aspects from the HTSM Systems Engineering Roadmap.

Key Technologies – Digital & Information Technology

Artificial Intelligence, Data Science, Data Analytics

The programme pays explicit attention to the application of data- and model-based systems engineering methodologies, where AI will be used to develop powerful engineering methodologies and tools (AI4Engineering). The ambition is to develop digital engineering assistants to at least double the efficiency and effectiveness of systems engineers. In addition, the programme investigates the potential consequences of integrating AI into high-tech equipment (e.g., regarding software/system testing, system safety, etc.): Engineering4AI.

Software Technologies and Computing

The programme focuses on systems engineering of high-tech devices, in which software (digital technology) plays a significant role. This means that the programme will pay explicit attention to software-related challenges. These may include testing AI-based and/or autonomous software and systems, efficient and effective software testing (verification), resource modelling and performance optimisation/diagnostics, hardware/software co-design, etc. The programme conducts research into the development of methodologies that can take the form of digital engineering assistants. This requires the use and development of software technology, including software engineering (in general), domain-specific languages, model-driven engineering, artificial intelligence, model-based low-code, etc.

Digital Twinning

Digital twinning will also be an important element in the research. This may include: digital/virtual engineering, virtual testing of systems, digital twins for diagnostics (system failures and performance degradation), digital twins for detecting and planning preventive maintenance, digital twins for generating system models (using AI), digital twins for training AI for purposes such as system calibration and optimisation, and digital twins for system simulation and performance optimisation.

Programme consortium

TNO ESI | Radboud University | TU Delft | TU Eindhoven | University of Twente | University of Amsterdam | ASML | Canon Production Printing | ITEC/Nexperia | Philips | Thales | Thermo Fisher Scientific | Vanderlande

Urgent transitions

Key enabling technologies

Circular economy

Digitalisation & Smart Industry

Knowledge and Innovation Agendas (KIAs)

KIA Key Enabling Technologies

KIA Health & Care

KIA Circulaire Economie

KIA Maatschappelijk

Verdienvermogen

KIA Security

Explainable synthesis of supervisory controllers

Poka Yoke 2025

Canvas 2025

CareFree 2025

Motif 2 Viper Qualification

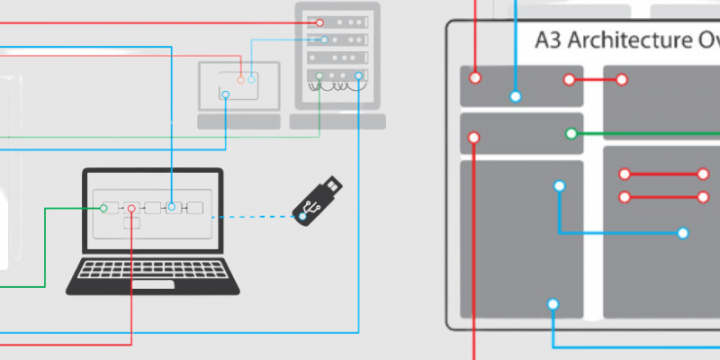

Bridging the gap between System Models and A3 Architecture Overviews

Systems Engineering for Human-Computer Collaboration at the Workplace

Discovering Engineering knowledge with LLMs Propelling Hybrid Intelligence 2024

Hybrid Analysis 2024

Large Language Models for Legacy 2024

Model-Based Testing with ComMA 2024

CareFree 2024

Programmes and projects

Holland High Tech supports programmes and projects in the sector High Tech Systems and Materials. Carried out in close collaboration between public and private partners within the mission-driven and innovation policy. Here is an overview funded R&D programmes and projects by Holland High Tech.